What Is Hydraulic System And How Does It Work

A water driven framework is an innovation that utilizations compressed liquid to produce, control, and send power. It works through the standards of liquid mechanics and liquid elements. This proficiency and power make water driven frameworks key in ventures requiring strong, dependable power transmission.

Envision an innovation that transforms a little drive into a strong power, controlling everything from vehicle brakes to weighty development gear. That is the sorcery of water powered frameworks, a cutting edge wonder that changes pressure driven strain into noteworthy mechanical strength.

Water powered frameworks work by using an incompressible liquid, commonly oil, to move force starting with one point then onto the next. At the point when power is applied to the liquid in a shut framework, it travels through water driven chambers or engines, empowering exact development and control in hardware and vehicles.

What Is A Hydraulic System

A water driven framework uses liquid to communicate force starting with one point then onto the next inside a shut framework. Regularly, this includes a water driven siphon that compresses the liquid, pushing it through lines and hoses to water driven chambers or engines.

These parts convert the liquid’s energy into mechanical power or movement, empowering exact control and strong activities. Ordinarily utilized in hardware, vehicles, and modern gear What Is A Hydraulic System, water powered frameworks offer benefits like high effectiveness, hearty execution, and the capacity to work under fluctuating circumstances with negligible support.

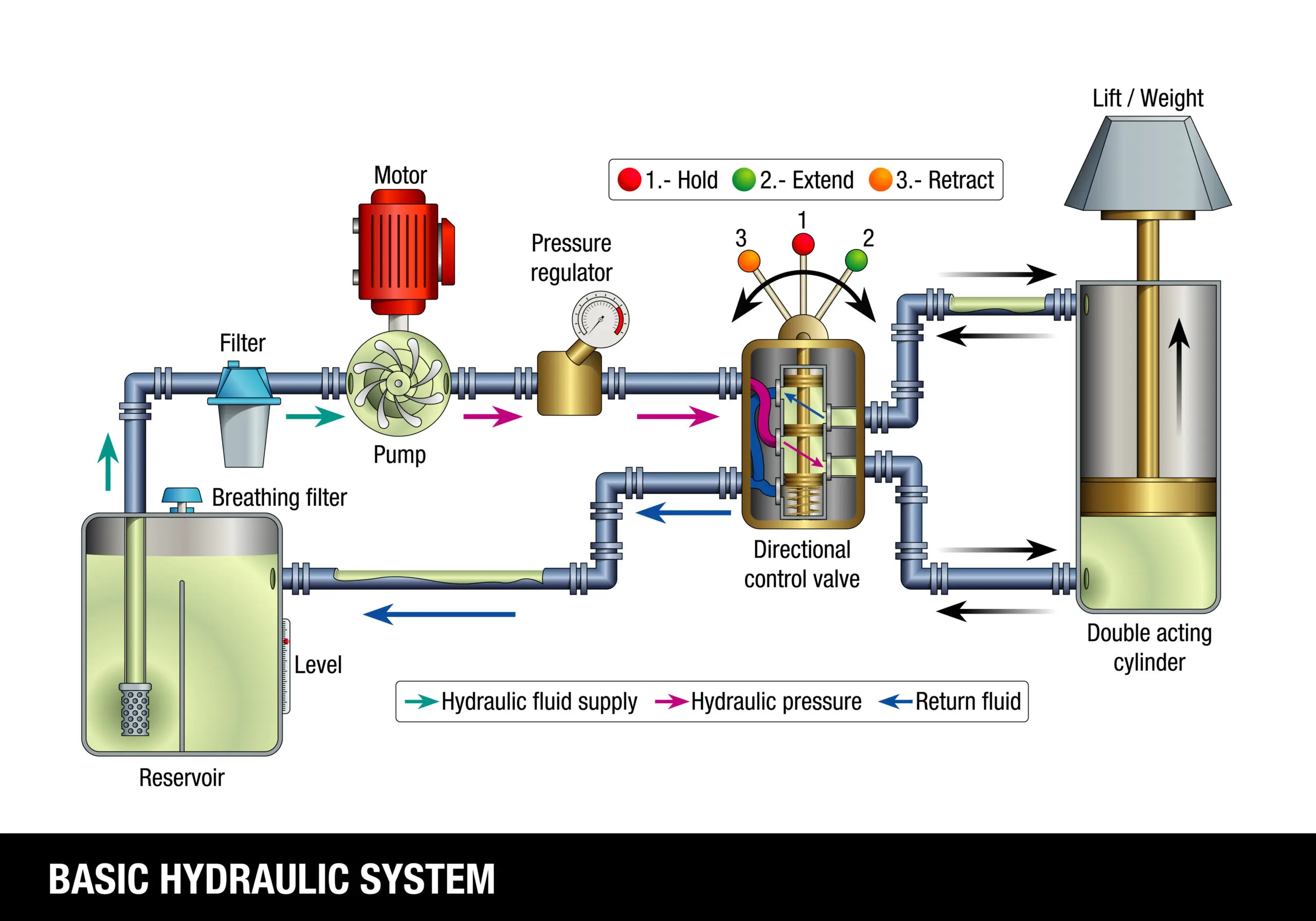

Overview Of Hydraulic System Components

A pressure driven framework contains a few key parts that cooperate to send power utilizing liquid. At its center is a water driven siphon, which compresses the liquid. This compressed liquid courses through hoses or lines to water powered chambers or engines, where it applies power to perform work.

Valves control the heading and measure of liquid stream, guaranteeing exact activity. Repositories store and keep up with the water driven liquid, while channels eliminate impurities to keep up with framework proficiency. These parts structure a solid and flexible framework involved across businesses for lifting, pushing, and controlling hardware with productivity and accuracy.

Why Is The Hydraulic System Preferred?

The water driven framework is liked for its capacity to send high power levels with accuracy and control. Dissimilar to mechanical frameworks Hydraulic Hose Factory, water power can work at high tensions, making them ideal for uncompromising applications like lifting and squeezing. They offer smooth and flexible movement, lessening mileage on parts.

Water driven frameworks additionally succeed in conditions where electric frameworks might present dangers because of sparkles or combustibility concerns. Their solidness, dependability, and capacity to work really in assorted conditions make them crucial in enterprises going from development and assembling to aviation and auto areas.

What Are Hydraulic High-Pressure Hoses?

Water powered high-pressure hoses are fundamental parts in pressure driven frameworks, intended to endure and convey compressed pressure driven liquid. Built from supported layers of engineered elastic or thermoplastic materials, these hoses keep up with primary respectability under outrageous tensions.

They include fittings at each finish to safely associate with pressure driven parts. High-pressure hoses guarantee productive transmission of water driven power between the siphon, valves, chambers, or engines, working with exact control and solid activity in different modern and portable applications.

Different Types Of Hydraulic High-Pressure Hoses

Water powered high-pressure hoses come in different kinds customized to explicit applications and working circumstances. Steel-built up elastic hoses are adaptable, offering strength and adaptability. Thermoplastic hoses succeed in high-temperature conditions and give astounding scraped area obstruction.

Wire-interlaced hoses upgrade strength and adaptability, ideal for tough applications. Winding wire hoses offer expanded strength and backing in high-pressure situations. Each type is picked in light of variables like tension rating, temperature range, adaptability requirements, and protection from wear and synthetic substances, guaranteeing ideal execution and wellbeing in different water powered frameworks.

Hydraulic Rubber Hoses With Reinforcement Metal Wires

Water powered elastic hoses with support from metal wires offer vigorous sturdiness and adaptability significant for requesting pressure driven applications. The metal wires, regularly steel, are interlaced or spiraled around the internal container of engineered elastic, giving solidarity to endure high tensions. This plan guarantees dependable execution under unique circumstances, opposing scraped area, erosion, and exhaustion.

These hoses keep up with adaptability for simple establishment and steering while actually sending water powered liquid to chambers, valves, or engines. Customary review and upkeep of these built up hoses are fundamental to forestall releases and guarantee continuous activity in modern and portable water driven frameworks.

FAQ’s

What Is The Rule Of Water Powered Framework?

The rule of a water driven framework includes communicating force utilizing compressed liquid. A siphon makes strain to move water driven liquid through hoses to chambers or engines, changing over liquid energy into mechanical power for exact control and strong tasks.

How Does Pressure Driven Power Work?

Water powered force works by compressing liquid with a siphon, which then, at that point, communicates this strain through hoses to chambers or engines. The liquid’s strain creates mechanical power, empowering exact development and strong activity in different modern and versatile applications.

How Do Pressure Driven Frameworks Work Which Liquid Is Utilized?

Water driven frameworks work by utilizing compressed liquid (commonly oil or manufactured pressure driven liquid) to communicate force. A water driven siphon compresses the liquid, which travels through hoses to actuators like chambers or engines, changing over water driven energy into mechanical power for exact control and strong tasks.

Conclusion

Hydrodynamics represent the clever use of liquid mechanics in driving hardware and frameworks across businesses. By saddling Pascal’s rule, water powered frameworks effectively convert liquid tension into mechanical power, empowering exact control and vigorous execution.

Their adaptability, from large equipment to airplane controls, highlights their crucial job in current designing. Progressions keep on refining pressure driven innovation, upgrading wellbeing, effectiveness, and supportability in assorted applications, guaranteeing proceeded with advancement in water powered frameworks.

Stay in touch with us for more updates and alerts! Aoomaal.Org